Purpose

Structural compatibility design lab

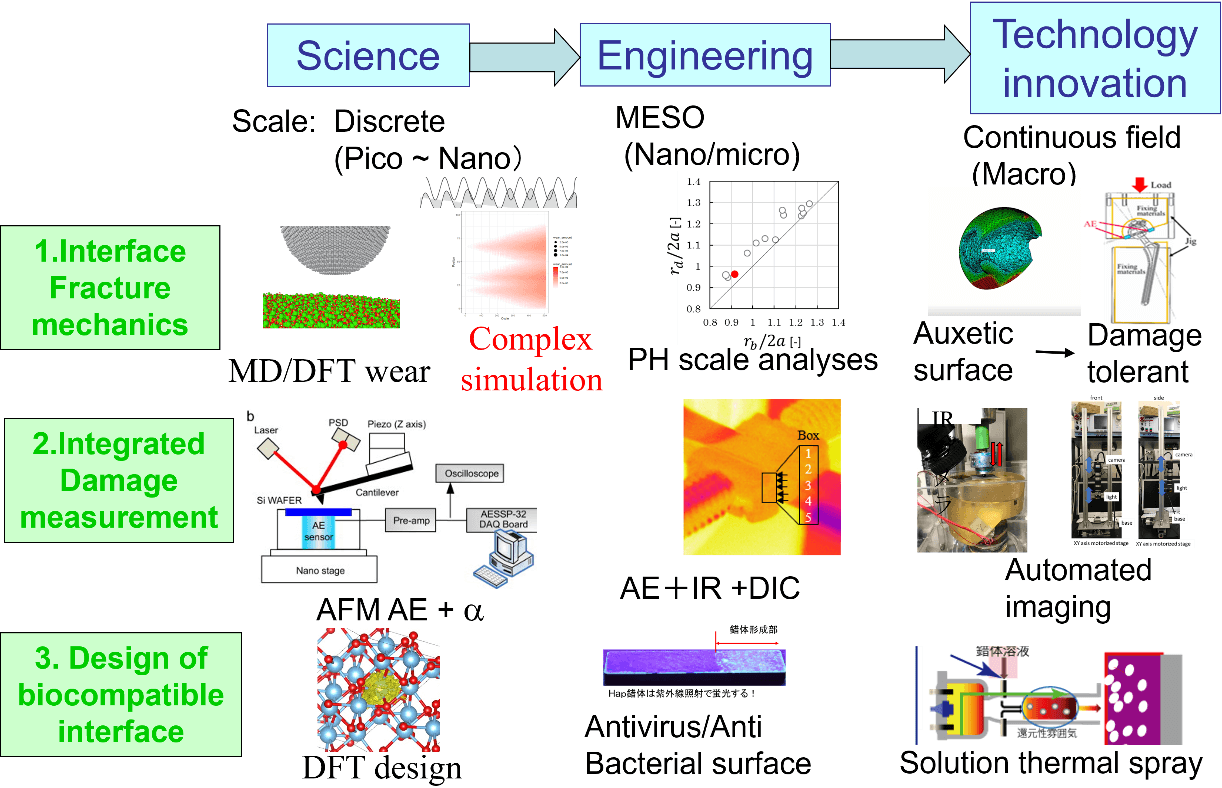

- Reveal mechanical mechanism o compatibility between artificial material surface with natural bio organs

- Control/Enhance mechanical interfacial compatibility using fracture mechanics approach.

- Measuring risk of interface cracks(delamination): Interface Fracture Mechanics

Our works are to reveal mechanism of wear and delamination at interfaces using fracture mechanics approach and stress singularity field. Fracture mechanics approaches will be used in material/interface design for advanced implants with ultralong lives. - Detecting interface damages:Integrated Damage Measurement

To detect initiation and propagation mechanism of wear and delamination at interfaces, integrated measurements system by Acoustic Emission (AE), Thermographic Camera (IR), Digital Image Correlation (DIC) are actively developed . Its integrated data processing method is also developed and applied for in-situ wear /delamination observation. - Design for mechanically compatible interfaces

Atoms/Nanoscale bonding mechanism between artificial materials and cells is considered. Especially inflammatory reaction induced by mechanical load and mechanobiology are considered. Surface topography design using advanced thermal spraying technology is also developed.

All topics consider multiscale/scale-up approaches from revealing atom nano scale mechanism(science),controlling networks of defects networks within stress concentration fields(engineering), design for integrated interfaces(innovation). We would like to reveal fracture mechanisms of interfacial delamination using both experiment and simulation approaches.